Grabber Guardrail System

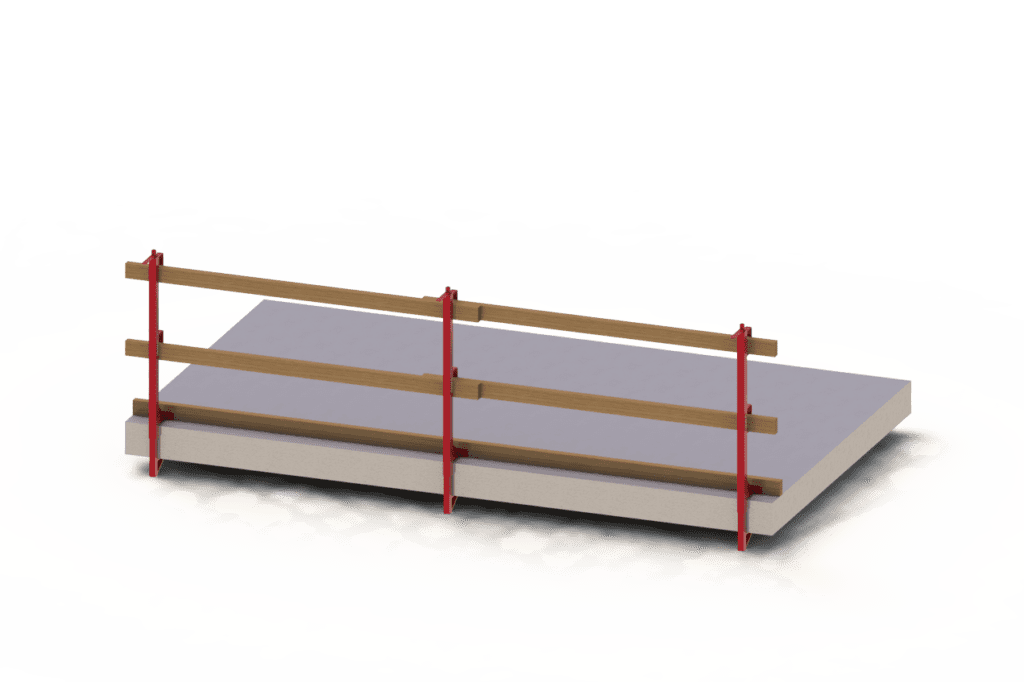

APAC provides slab grabber guardrail systems for fall protection applications. The slab grabber guardrail system is used to prevent workers from crossing the slab edge and can be used as an alternative to falling protection or safety net systems. The slab grabber fall protection system is to be placed on any leading edge where there is a risk of falling.

APAC manufactures and supplies the Slab Grabber Guardrail Fall Prevention System that is compliant with all OSHA 1910, 1926 Subpart M regulations and EN 13374.

Slabber Guardrail System For You

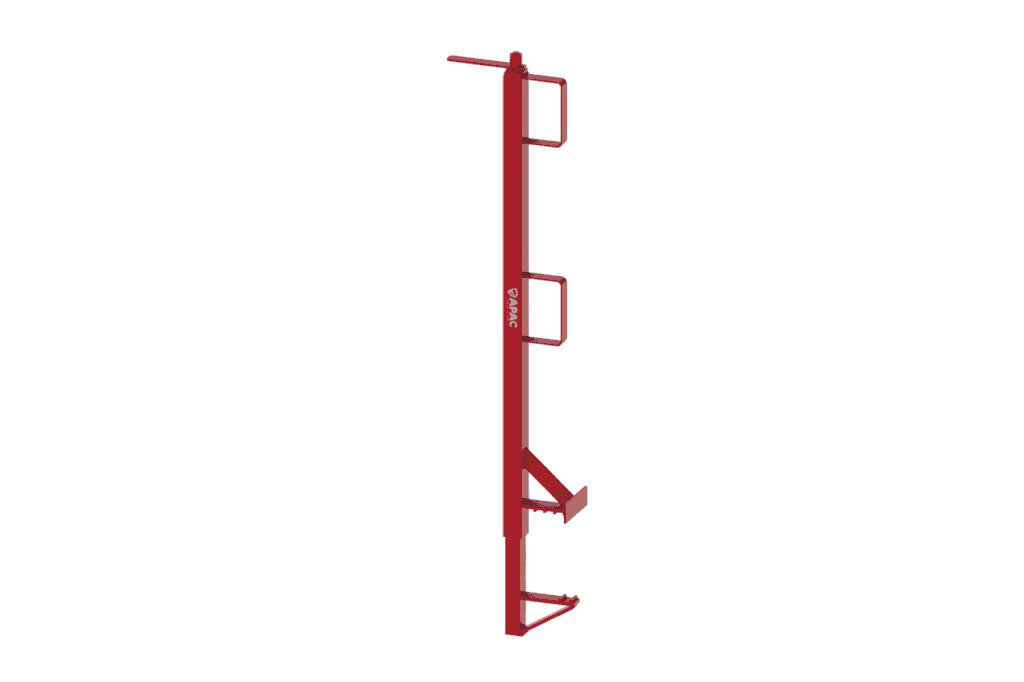

The Slab Grabber for the Guardrail System is made from Q235 steel material with a powder-coated or galvanized surface finish. Slab Grabber can be adjusted to fit concrete beams from 3” to 36” thick.

Allowable spacing between Slab Grabbers is 2.4m handrails and toe boards for the slab grab guardrail system are 2 x 4 or 2 x 6 construction grade timber. The top rail must be 42″ (+/- 3″) above the working surface following OSHA standards.

For the installation, slab grabbers must be installed flush with the substrate and must allow the guardrail posts to be positioned vertically to the work surface. Qualified personnel must consider the concrete substrate compatible with the Slab Grabber.

Full-Cycle Manufacturing Serve You At Every Stage

APAC is a full-cycle manufacturer, from raw material to the molding of finished edge protection systems. This allows us to ensure the minimum timescales & lead times, and quality at every stage of production.

- Material Incoming Inspection

- Automatic production lines

- Products Tracking Number

- Perform Testing upon your request

On-Time Delivery Service You Can Trust

Throughout the entire process of APAC management, a credible supply chain is vital and very important for the success of our business so far. With years of firm cooperation with freight forwarders, we have become experts in what is of the utmost importance to you—on-time delivery.

No matter it is a sample, trial order or bulk item, we will track deliveries and monitor the ongoing performance of our haulers to ensure high standards of care and punctuality are maintained for your slab grabber guardrail systems.

-1024x283.png)